| Epoxy hardener H-3258 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

YGLUE™H-3258

1.Specification:

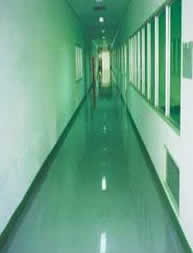

the hardener H-3258 is a low viscosity, light color hardener for use in modified aliphatic amine epoxy resin. After curing, the solidification surface is gloss and can bear the acid and alkali, resist rub and high pressure. Thanks to its excellent properties, it lends itself to the production of light-resisted insoluble paint, or the flooring paint above 5℃.

2. Mixing Ratio:

BPA Epoxy Resin (With Epoxy Equivalent of around 190): 100 parts by weight

Hardener H-3258: 50-60 parts by weight.

3. The Curing properties

3.1 Heating Properties: The following chart shows the heating properties of the hardener under room temperature of 23℃ with total weight of 100G.

3.2 Desiccating Properties: The following chart shows the RCI Desiccating Properties of the hardener with the above mentioned mixing ratio (Thickness of the Desiccating Film: 150um):

4. Physical Properties (According to JISK6911)

Curing: 7 days at room temperature of 23℃

Epoxy Resin: BPA Epoxy Resin with Epoxy Equivalent of about 190.

5. Reagents Resistant Properties: The following chart shows the ratio of the weight changing

Curing: 7 days at room temperature of 23℃

Epoxy Resin: BPA Epoxy Resin with Epoxy Equivalent of about 190.

6.Pot life: 35-40 Minutes of total weight of 100 Grams with the above mentioned ratio under 25℃。

7. Package and Storage:

It is packed in 200KG Iron Drum. Storage should be under cool circumstance. And please close well after it is opened.

8. Shelf life: 2 years in sealed container.

H-3238 modified cycloaliphaticamine transparent

H-3258 modified cycloaliphaticamine transparent, slight yellow

H-1138 modified aromaticamine

H-6138 modified aliphaticamine |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||